At Ideal Valve Inc., our brass needle valves are engineered for precision flow control in both gas and liquid systems. The 51 Series of Needle Valves is ideal for applications that require metering larger flows than our standard 52 Series (Brass) or 54 Series (Stainless Steel). Each valve provides accurate regulation and consistent performance, making them a trusted choice for engineers and technicians who rely on precision valves for instrumentation and flow systems.

51 Series Brass Needle Valve Features

Our 51 Series valves are built to handle pressures up to 3000 psi, with a temperature range from -65º to 450º F. Two models, 51-8-31E and 51-12-41E, use a bar stock brass body, while all other models feature a durable cast bronze body. Each valve undergoes factory testing to ensure leak-tight performance at 1100 psi, giving you confidence in every application.

Key specifications include:

• Teflon packing seal for smooth operation

• Stainless steel needle for durability

• Metal-to-metal seat for precision metering

• 1.75″ phenolic plastic knob for easy adjustment

• Bronze body, bonnet, and seat construction

• 32 threads per inch for fine control

• 22-24 turns from shutoff to full open

Custom Needle Valves & Flow Solutions

In addition to standard 51 Series valves, Ideal Valve Inc. offers custom needle valves and custom flow components to meet the specific needs of your system. Whether for industrial instrumentation, laboratory applications, or flow control solutions in water features and pond filtration systems, our valves provide reliable performance and precise adjustment.

Why Choose Ideal Valve

With decades of experience in valve manufacturing and flow control expertise, our team delivers valves designed for accuracy, durability, and consistent performance. Ideal Valve Inc. is your partner for precision brass needle valves and comprehensive flow control solutions.

Request Your Brass Needle Valve

Ready to specify a brass needle valve for your project? Contact us today to discuss your flow control needs or request a custom solution from our team of experts.

Dimensions

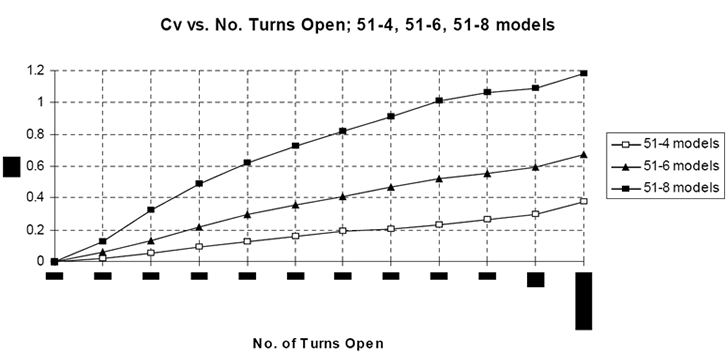

Cv vs. No. Turns

Flow Characteristics of Models

| No. Turns Open | 51-4 Cv (gpm) | 51-6 Cv (gpm) | 51-8 Cv (gpm) |

|---|---|---|---|

| 1 | 0.02 | 0.07 | 0.13 |

| 2 | 0.05 | 0.14 | 0.33 |

| 3 | 0.09 | 0.22 | 0.48 |

| 4 | 0.12 | 0.30 | 0.62 |

| 5 | 0.16 | 0.35 | 0.73 |

| 6 | 0.19 | 0.41 | 0.82 |

| 7 | 0.21 | 0.48 | 0.91 |

| 8 | 0.23 | 0.52 | 1.01 |

| 9 | 0.27 | 0.57 | 10.6 |

| 10 | 0.30 | 0.61 | 1.09 |

| Full Open | 0.38 | 0.67 | 1.18 |

Selction Guide

| Item # | Orifice | Port | Cv | Max. A | B | Type | Mounting Holes |

|---|---|---|---|---|---|---|---|

| 51-4-21 | 0.125 | 1/4″ | 0.375 | 5.84 | 0.79 | Straight Pattern | N/A |

| 51-6-21 | 0.1875 | 1/4″ | 0.67 | 5.84 | 0.79 | Straight Pattern | N/A |

| 51-6-23 | 0.1875 | 1/4″ | 0.67 | 5.84 | 0.97 | Mounting Flange Straight Pattern | 10-32 |

| 51-6-24 | 0.1875 | 1/4″ | 0.67 | 5.84 | 0.79 | Straight Pattern | N/A |

| 51-8-31E | 0.25 | 3/8″ | 0.90 | 6.00 | 0.97 | Straight Pattern | N/A |

| 51-8-32 | 0.25 | 3/8″ | 1.08 | 6.25 | 1.14 | Angle Pattern | N/A |

| 51-8-33 | 0.25 | 3/8″ | 1.08 | 6.00 | 0.93 | Mounting Flange Straight Pattern | 10-32 |

| 51-12-41E | 0.375 | 1/2″ | 2.65 | 7.00 | 1.1 | Straight Pattern | N/A |

| 51-14-61E | .4375 | 3/4″ | 3.10 | 7.25 | 1.1 | Straight Pattern | N/A |